Contact Supplier

Mr. Terry Zhou

Leave a messageBasic Info

Model No.: ETS

Brand: ETR

Usage: Oxygen

Purpose: Gas separation

Parts: Gas Tank

Application Fields: Medical

Noise Level: Low

Machine Size: Large

Condition: New

Certification: ISO

Color: White

After-sales Service Provided: Engineers Available To Service Machinery Overseas

Power: 60W

Technology:: Pressure Swing Adsorbtion (PSA)

Purity:: 93+/-3%

Advantage: App-monitoring

Filling Pressure:: 150bar/Customized

Filling Capacity:: 2-400Bottle

Application:: Medical

Additional Info

Packaging: Wooden case of standard export package

Productivity: 50 Sets/Month

Transportation: Ocean,Land

Place of Origin: Made in China

Supply Ability: 50 Units per Month

Certificate: ISO9001

HS Code: 841960019000

Port: Shenzhen,Shanghai,Guangzhou

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW,FCA

Product Description

PSA Oxygen Gas Plant for Cylinder Refilling

1.Oxygen Cylinder Refilling Plant Description

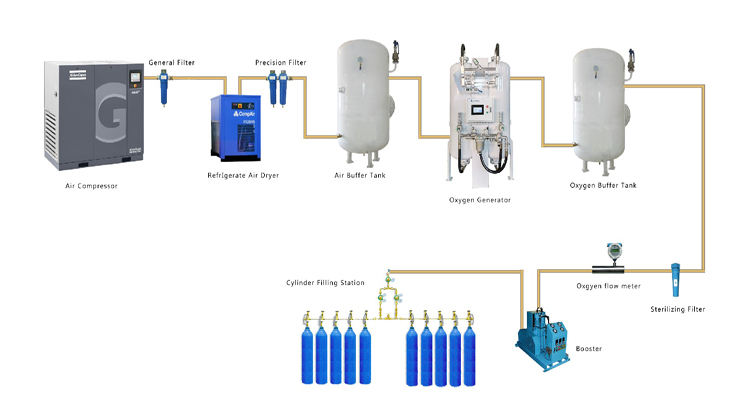

With PSA principles, ETR Two-Towers PSA Oxygen Cylinder Refilling Plant can produce 93%±3% purity oxygen gas directly from compressed air. The oxygen cylinder refilling System is consisted of Atlas Copco air compressor, SMC refrigerate air dryer and filters, air buffer tank and oxygen buffer tank, ETR PSA oxygen gas plant, oxygen booster and Oxygen Filling Station.

Compressed air is purified through the air dryer and filters to a certain level for main plant to work with. Air buffer is incorporated for smooth supply of compressed air thus to reduce fluctuation of compressed air source. The plant produces oxygen with PSA (pressure swing adsorption) technology, which is a time proven oxygen generation method. Oxygen of desired purity at 93%±3% is delivered to oxygen buffer tank for smooth supply of product gas. Oxygen in buffer tank is maintained at 4bar pressure. With an oxygen booster, the oxygen pressure can reach to 150bar, and then fill in cylinders with an Oxygen Cylinder Filling station.

2. Oxygen Cylinder Refilling Plant Advantage

• Time proven PSA technology ensure the stable and economical of the system

• Can produce oxygen based on the actual demand

• Automatically control and monitor

• Easy installation and operation and maintenance.

• Small machine room area

• Energy saving.

3. Oxygen Cylinder Refilling Plant Quality Control Process

ETR Engineering & Technology,clients can be sure of the quality of ETR solution. ETR uses only the best suppliers and components. And all oxygen generators are tested & commissioned by professional Experts to make sure everything is qualified before they leave the factory.

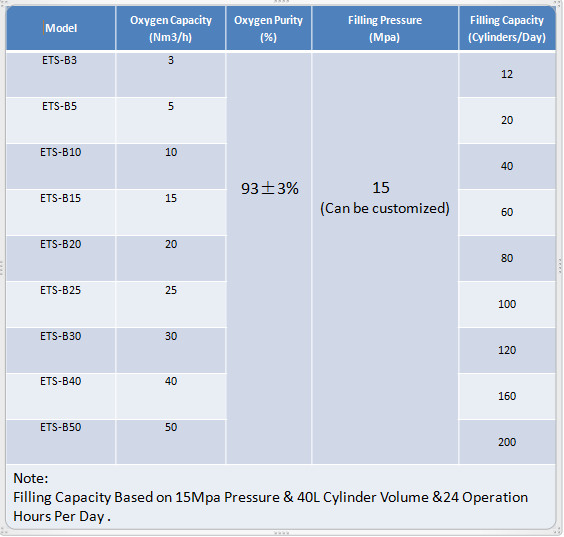

4. Oxygen Cylinder Refilling Plant Model Select

Eter founded in 2003 and listed on the NEEQ (National Equities Exchange and Quotations) with the stock code of 839074 in 2016.

Eter is the mainly Integrated Solution provider for Medical Engineering such as medical oxygen generation solution/vacuum negative pressure suction solution/ medical oxygen cylinders filling solution/Hospital Bed Head Unit solution/Nurse Call System etc.

Eter is the one of most qualified producers in China market. In addition to the International market, the ETR products have been exported to Southeast Asia, Africa, the Middle East and other overseas markets.

Eter is UN qualified product supplier.

Product Categories : Oxygen Cylinder Filling System > Onsite Oxygen Cylinder Filling System

Product Images